Plasma Treatment Articles

Plasma Activation,

Plasma Treatment

|

3 min read

Topic:

Manufacturers and researchers often question if they are using the right adhesion promoter in product development. This can be a very challenging question because so many materials have different surface energy levels and different geometries that need to be bonded after they have been created. Often the best option which addresses the real problem is not chosen and poor bonding results.

A siloxination agent is a choice that many manufacturers have used to enhance the adhesion between materials with very low surface energy. These bonding agents do not actually increase the surface energy of the base material. Instead, a base layer of another material or solution is applied to the surface so that the subsequent bonding material may then be applied and bonded to that siloxination agent. This can often create a poor bond between the siloxination agent and the base material or the siloxination agent and the part to be bonded to it after application. An alternative, better method is to find a solution that will increase the base material's surface energy so that the siloxination agent can be removed entirely. Plasma treatment with a plasma system with proper chemistry can improve many different materials' surface energy to be adequately bonded.

A siloxination agent is a choice that many manufacturers have used to enhance the adhesion between materials with very low surface energy. These bonding agents do not actually increase the surface energy of the base material. Instead, a base layer of another material or solution is applied to the surface so that the subsequent bonding material may then be applied and bonded to that siloxination agent. This can often create a poor bond between the siloxination agent and the base material or the siloxination agent and the part to be bonded to it after application. An alternative, better method is to find a solution that will increase the base material's surface energy so that the siloxination agent can be removed entirely. Plasma treatment with a plasma system with proper chemistry can improve many different materials' surface energy to be adequately bonded.

When using an adhesion promoter, they typically have a low shelf life, leading to scrap that needs to be disposed of. If the adhesion promoter is not used in a timely fashion, it must be discarded, which is a loss. Manufacturing waste should be avoided whenever possible. Adhesion promoters also often contain hexane, which is hard to dispose of in a manufacturing environment. It is also very hazardous to humans, where it can cause damage to internal organs when inhaled. Plasma systems do not have any hazardous effects and can be used multiple times if the product is not ready for bonding immediately after treatment.

Adhesion promoters can be very expensive to purchase and use. The continual use of adhesion promoters requires the repeated purchase as it is a costly consumable. The adhesion promotion process is different when using a plasma system. Plasma systems can be repeatedly used with minimal material input requirements. The only consumable required is electricity and process gas, which only amounts to a small cost, especially because many processes will use atmospheric air pulled in from the air in that particular manufacturing environment.

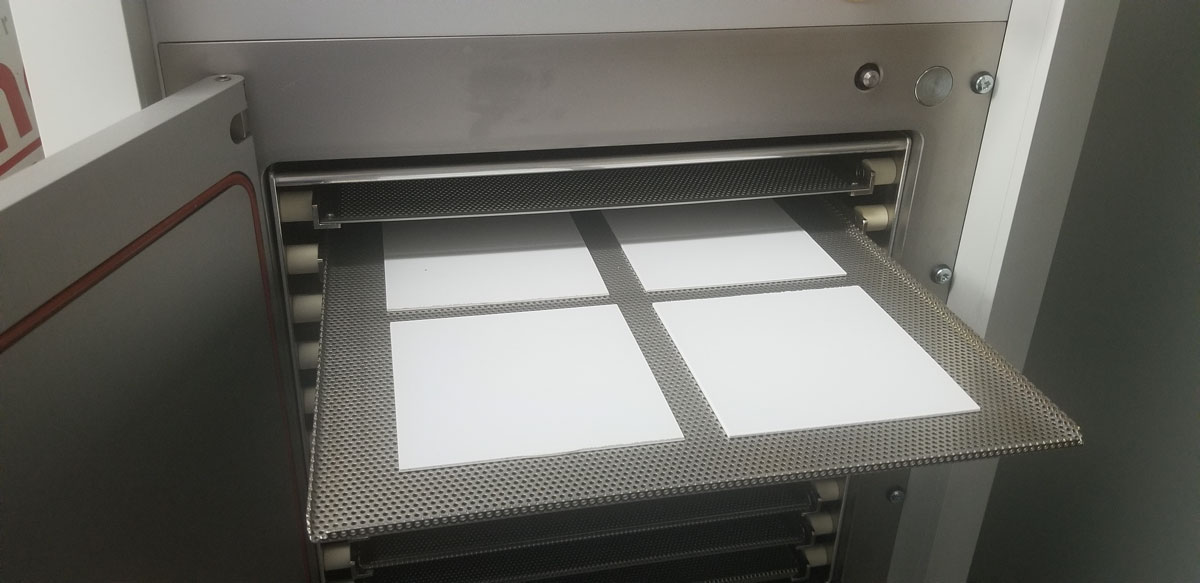

The use of an adhesion promoter can add significant time to a manufacturing process. The additional time is because that promoter has to cure and evaporate for it to take effect. The promoter's application can also take time to be sure that it is applied to the entire surface that needs to be bonded and evenly so that there aren't places where the bonding process can fail. Uniform application of the adhesion agent is a challenge in itself. Plasma activation can be performed inline and reduces takt time, which will make the manufacturing line quicker and more efficient. Plasma also allows for a higher production rate by removing a choke point in the manufacturing process.

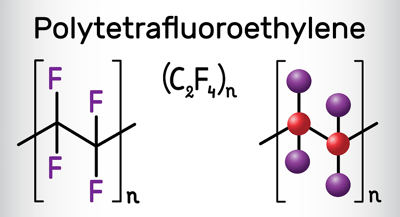

One example of a material that has low surface energy would be PTFE (Polytetrafluoroethylene). This material is a fluorine-containing plastic that is quite difficult to bond to. Due to the nature of low surface energy in PTFE, many manufacturers turn to an adhesion promoter to bond to it. PTFE adhesion promoters are not as efficient as a hydrogen plasma treatment with a plasma system to raise that surface energy. An adhesion promoter does not change the PTFE surface energy but instead adds a layer of different material to try to achieve the same effect. The plasma treatment is more cost-effective, time-efficient and solves this material's low surface energy central issue.

One example of a material that has low surface energy would be PTFE (Polytetrafluoroethylene). This material is a fluorine-containing plastic that is quite difficult to bond to. Due to the nature of low surface energy in PTFE, many manufacturers turn to an adhesion promoter to bond to it. PTFE adhesion promoters are not as efficient as a hydrogen plasma treatment with a plasma system to raise that surface energy. An adhesion promoter does not change the PTFE surface energy but instead adds a layer of different material to try to achieve the same effect. The plasma treatment is more cost-effective, time-efficient and solves this material's low surface energy central issue.

Plasma activation is an excellent way to increase the surface energy of low energy parts to perform a bonding process. It is superior to an adhesion promoter because of the cost savings, reduced takt time, and uniform treatment. Plasma treatments can also wholly replace siloxination agents in the manufacturing process. Plasma systems are environmentally friendly and do not produce scrap. Manufacturers that implement plasma systems into processing lines often find that they save time and money by producing more products per hour and eliminating the current choke point in their process. Many different materials can benefit from switching to a plasma process. The overall quality of the product will increase while reducing the cost as well.

To learn more about the benefits of surface activation of low surface energy materials in the manufacturing process, please read our article titled "Manufacturer’s Surface Activation Guide for Improved Adhesion."

Comments