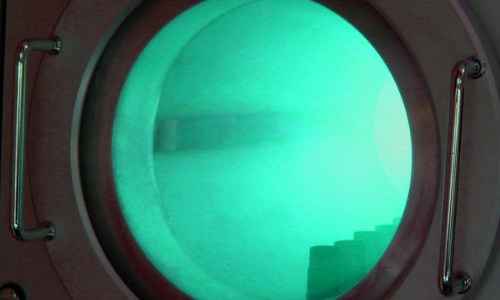

Plasma systems can clean, activate, etch, or coat surfaces in ways not achievable by other surface treatment technologies. For this reason, Thierry offers a complete range of plasma systems for every application. Plasma systems differ by technology – low pressure and atmospheric pressure – as well as by size and design.

We offer process development, system rentals, and contract service at our facility. In addition to our large inventory of standard plasma systems, we also specialize in custom built systems to best suit your needs.

Plasma technology and its different processing methods are used in many industrial contexts due to its vast potential when it comes to modifying surfaces. There are different plasma technologies depending on the desired effect to be achieved in your materials.

What makes plasma technology so attractive are the many application possibilities that can be customized according to each customer’s needs. Plasma-modified surfaces play a crucial role in many industries. This process of plasma surface modification is performed at a dry molecular level by each of the respective methods.

Plasma surface technology is a growing industry modifying the characteristics of a surface and its properties – from changing adhesive bonding performance to making surfaces hydrophobic, etching specific structures, or cleaning them on a molecular level.

We are dedicated to creating and delivering surface modification solutions that improve the manufacturing process and profitability of our customers as well as supporting university research. Our full-service staff is committed to providing complete solutions from concept to delivery. Before a client buys or rents a plasma system we guide them with plasma process development to ensure their success. Contract service is also an available service option.

Plasma: +1 (248) 761 9253

Distribution: +1 (248) 549 8600

Fax: +1 (248) 549 3533

info@thierry-corp.com