We are a full service provider of surface modification plasma processing solutions.

Our main focus is providing equipment and services for plasma cleaning, activation, etching, and deposition.

If your project needs process development, piece part work or additional support we are ready to discuss your application and offer solutions.

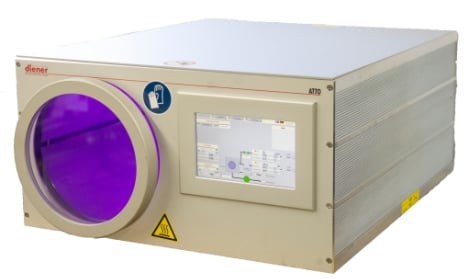

The first step in evaluating plasma solutions is to do a test study. In a test study, the client provides sample materials for our lab to perform a simple screening test and evaluation of the impact of plasma on surface quality. As an example, in a material activation test study, we would measure surface energy before and after plasma activation and document the difference between the two surface states. In all cases, we provide a detailed report and summary of recommendations to our client.

The plasma test study is used as a way to gather data to evaluate suitability of plasma in your manufacturing process. We perform plasma test studies for plasma etching, plasma cleaning and plasma deposition processes as well as plasma activation.

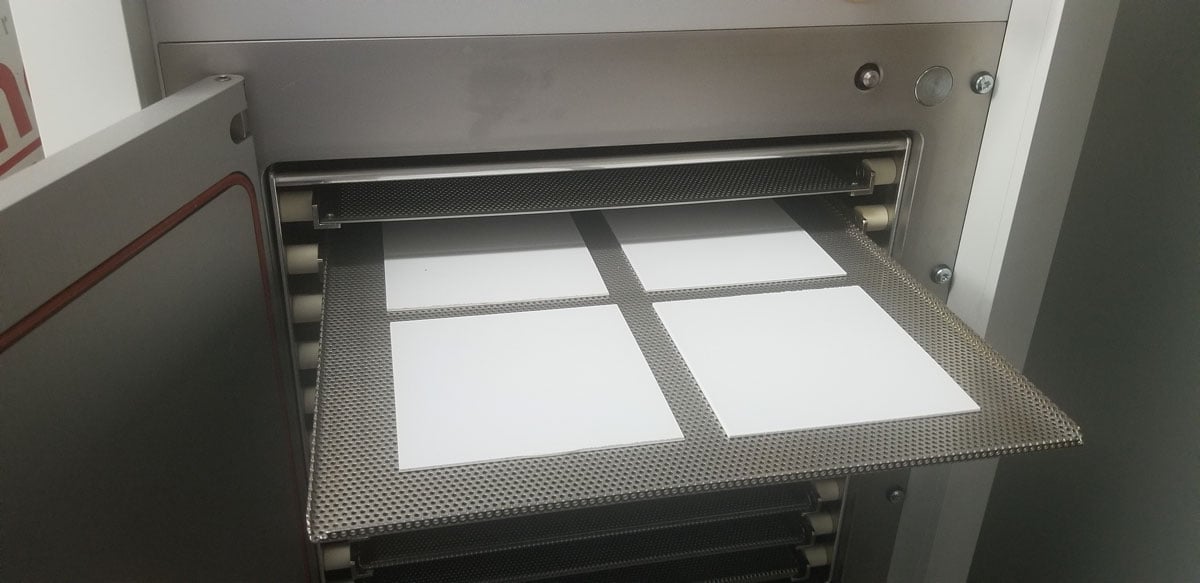

For clients who need plasma treatment of components quickly or as an operating expense, we offer plasma treatment services at our Royal Oak Michigan facility. Manufacturers who are interested in exploring outsourcing plasma treatment services should request a plasma treatment outsourcing discussion.

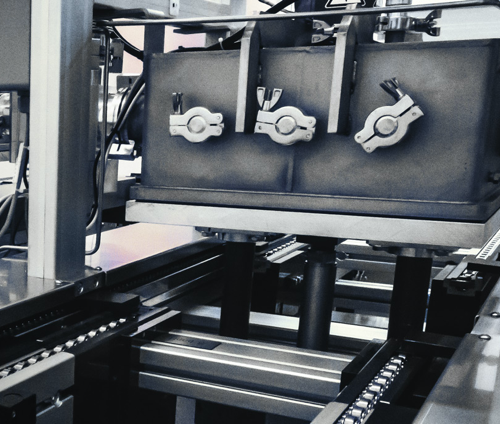

One of advantages of having years of plasma processing experience in the lab and in many manufacturing applications is the ability to help clients select and optimize the right plasma system and integration into their manufacturing process. Our discussions span from the very simple plasma treatment system to full custom plasma systems for high-throughput manufacturing operations. To identify the right plasma system for your process needs, request a plasma system exploratory discussion.

All plasma systems need regular maintenance to perform reliably. Most clients develop their own maintenance program, like they would on any other manufacturing system. Many clients request on-site maintenance once or twice a year based on usage patterns and performance metrics. If you are seeking maintenance support for your plasma system, request a maintenance discussion.

When a client purchases a plasma system they sometimes require assistance with plasma system installation and training. Our experienced staff is available to visit on-site to assist with system installation and provide your team with plasma system usage and maintenance training. Learn more about plasma system installation and training.

Plasma system rentals are offered to enable our clients to gain fast access to systems for early development of a manufacturing process verification or to circumvent the delivery time of their production system. A discussion with us will enable an understanding of your application needs so we may recommend the best solution for you.

Often plasma technology is a core competency that a client would like to add to their internal value stream portfolio. In many cases, few employees have experience with the application and use of plasma processing. To address this need, we provide an in house plasma processing workshop. This workshop offers instruction and an extensive question and answer session about the field of Plasma Technology. Learn about a plasma processing workshop.