Plasma Treatment Articles

Plasma Activation,

Plasma Treatment,

Overview Activation

|

3 min read

Polypropylene (PP) is a thermoplastic superhero, ideal for manufacturing tough, robust products ranging from car bumpers and medical devices to high-performance fabrics for harsh environments. In fact, polypropylene is used to make products found in just about every major industry and market.

However, polypropylene is a polymer with relatively low surface energy, requiring it to be modified to better accept a variety of treatments, such bonding, painting, and coating. Recently, plasma treatment has become increasingly popular as a surface activation and modification technique for a wide range of polypropylene products, including textiles, where it’s used to enhance material wettability. Many manufacturers now use plasma systems to perform surface preparation to enhance bonding and adhesion performance for products throughout the consumer, commercial, and industrial worlds.

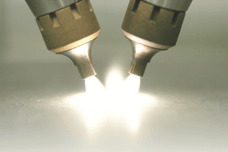

There are 3 primary plasma system options for treating polypropylene:

|

Atmospheric Plasma

|

|

Low Pressure Plasma This type of system generates plasma in a chamber that has been evacuated and then injected with small amounts of gas – usually oxygen, argon, hydrogen, nitrogen, or air. This method is better-suited for large batch parts processing and can easily handle difficult geometries. |

|

Corona Plasma

|

There are several ways to use plasma systems to activate polypropylene depending upon the treatments needed for the specific product. Here are some examples of how the methods described above are used to enhance this thermoplastic material:

Wettability is a surface characteristic that is defined as the tendency of a fluid to spread or adhere to a solid surface and the ability of that surface to hold contact with it. One way to measure wettability is to use a test that registers a unit of force called a dyne.

Most manufacturing applications in which good wettability is desired require at least 72 dynes as a benchmark for acceptable product performance – a result difficult to achieve with polypropylene’s inherent low surface energy. By activating the surface of the polypropylene with plasma, its surface energy can be increased from 28 dynes to more than 105 dynes – well beyond the acceptable performance level. This significant improvement increases the number of manufacturing applications for polypropylene and its value as a versatile raw material, reinforcing its reputation as a workhorse of the thermoplastic industry.

Atmospheric, low-pressure, and corona plasma systems are all well-suited for production line integration. Flexible, versatile, and streamlined for manufacturing use, these methods are efficient and effective, capable of providing highly accurate, automated, and reliable service in high-volume production environments. Plasma activation of polypropylene on an automated production line can occur at rates of 100 to 400 mm/second, and batch processes can occur in process times of less than 10 minutes for a large batch of parts.

Unlike other surface treatment technologies that produce toxic by-products and pose health risks for workers, plasma technology is a cost-effective solution that does not produce any volatile organic compounds, providing a safe industrial hygiene environment that protects worker health.

Manufacturing process development using plasma to treat polypropylene is simple to implement and is a highly reliable form of surface treatment. The combination of polypropylene’s popularity and the availability of high-quality, cost-efficient plasma systems make them a perfect combination for developing and manufacturing new and innovative products.

Discover how your business can utilize plasma activation technology to modify polypropylene surfaces for high-performance bonding, coating and painting. Downloading the eBook, "Manufacturer’s Surface Activation Guide for Improved Adhesion" to learn more.

Comments