Plasma Treatment Articles

Plasma Activation,

Plasma Cleaning,

Plasma Coating

|

3 min read

Topic:

There are seemingly countless types of coatings that can be applied to component surfaces using plasma treatments. These coatings are typically developed to perform a function really well, such as to serve as an adhesive, or to protect the surface from an environmental hazard.

One of the most popular coatings designed to reduce friction is carbon film. Plasma deposited carbon film features an exceptionally low coefficient of friction, enabling components to last longer, ease assembly, reduce assembly damage, reduce early cycle damage, feed reliably in a vibratory bowl feeder, and potentially reduce parasitic losses associated with friction. Because of its extremely low friction coefficient and wear rate, plasma deposited carbon coating offers a way to make rolling, sliding, or rotating elastomeric parts more efficient and long-lasting.

Plasma deposited carbon coating reduces friction by factors of 20 to 100 below the levels feasible with existing low-friction materials, coatings, or lubricants. In aerospace and transportation systems, such reduction in friction translates directly into higher efficiency and better, quieter performance. Overall lower wear results in longer component and system lifetimes and lower maintenance costs.

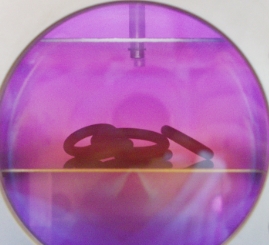

Even in less mission-critical applications, carbon coatings can be highly useful. For example, elastomeric parts often stick together or are tacky, which makes them difficult to handle, assemble, or bowl feed in manufacturing processes. Applying a carbon coating to elastomeric components lowers the coefficient of static friction on their surfaces without affecting the bulk properties of the finished parts, making them much easier to handle or process.

Key advantages provided by plasma deposited carbon coatings when applied to moving parts and mechanical assemblies include:

The first step in the carbon film coating process is plasma cleaning, which enables the component surface to be free of all contaminants using a variety of chemistry options which also renders the surface hydrophilic, decreasing the water contact angle and increasing wettability to enhance the bonding or adhesion of the coating to the surface. This activation is caused by injecting a small amount of gas, or “feedstock,” into the chamber where an electric field between electrodes accelerates electrons which then impact other gas molecules. These collisions create more free electrons, neutrals, molecular short-strings, and ions. As these reactive gas or plasma components interact with the surfaces of parts in the chamber, the molecular bonds of the first 1 to 5 layers of surface molecules are broken, “activating” them.

The first step in the carbon film coating process is plasma cleaning, which enables the component surface to be free of all contaminants using a variety of chemistry options which also renders the surface hydrophilic, decreasing the water contact angle and increasing wettability to enhance the bonding or adhesion of the coating to the surface. This activation is caused by injecting a small amount of gas, or “feedstock,” into the chamber where an electric field between electrodes accelerates electrons which then impact other gas molecules. These collisions create more free electrons, neutrals, molecular short-strings, and ions. As these reactive gas or plasma components interact with the surfaces of parts in the chamber, the molecular bonds of the first 1 to 5 layers of surface molecules are broken, “activating” them.

To deposit plasma carbon coating onto a component, carbon-containing feedstock is introduced to the plasma vacuum chamber, depositing the carbon onto the surface. This process can be done with parts on a tray or, even better, in a vacuum chamber that can bulk-tumble the parts for uniform higher volumes and shorter processing times. This carbon-deposition process can typically produce a coating of 20 to 200 nanometers in 10 to 60 minutes.

To determine the quality of a low-friction carbon film coating during manufacturing, an automatic incline plane is used to measure slip angle – the angle of a surface at which an item begins to slide off of it. When the surface’s plane exceeds the angle at which static friction no longer holds the part in position, the measurement system stops the incline and records the angle. Properly coated parts have a typical slip angle of 15 to 25 degrees – a significant reduction from an uncoated part’s usual slip angle range of 50 to 70 degrees.

Whenever possible, a rotary drum vacuum chamber is preferable over a non-rotary system because it substantially reduces the amount of time and labor needed to process parts that are small or difficult to handle. The rotary action, combined with vacuum plasma technology, ensures that every surface of a small, complex part gets evenly coated while the smaller form factor of a rotary vacuum chamber takes up less floor space in a manufacturing facility than a non-rotary system, making the entire manufacturing process line more compact and efficient.

Contaminants pose a significant risk to coating quality and consistency – it is critical to perform the coating process in as pristine an environment as possible. Fortunately, plasma vacuum chambers can self-clean themselves when necessary, depending on the coating and the production volume, just by replacing the carbon-containing feedstock with oxygen or even air.

Low-friction carbon coating by plasma-enhanced chemical vapor deposition is an excellent manufacturing option for applying low-friction coatings on elastomeric or rubber parts. Plasma is an excellent choice for any size application, whether it’s a small batch of 50 to 100 parts or a large batch run containing thousands of parts at a time. If you would like to see how a carbon coating would affect the friction of your parts, please request a Plasma Processing Test Study.

Are you interested to learn more about how coatings enable manufacturers to improve the quality of their products? Please consider downloading our eBook titled "The Manufacturer's Plasma Coating Playbook" to learn about coating applications. If you are interested in speaking to an expert in plasma applications, please consider reaching out and scheduling a plasma treatment overview discussion.

Comments