Plasma Treatment Articles

Plasma Activation

|

4 min read

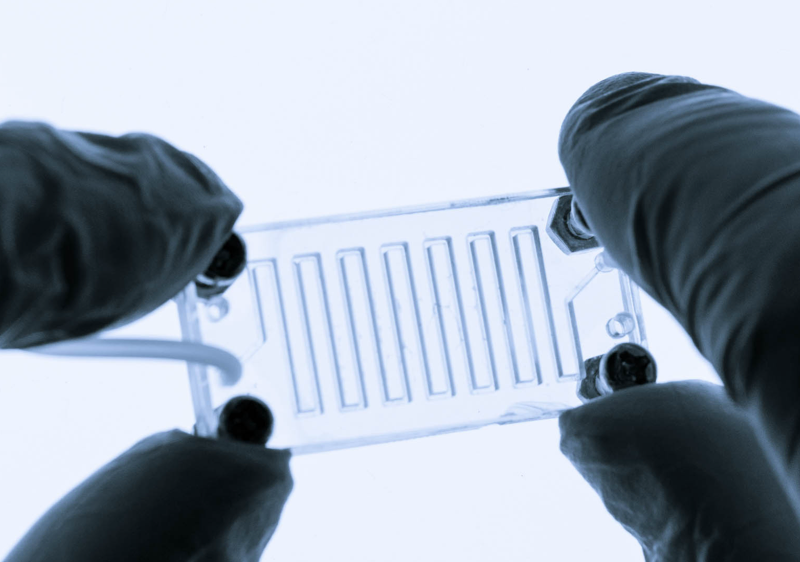

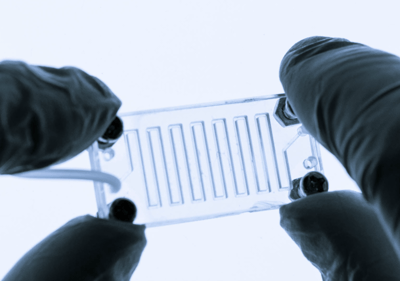

When developing or manufacturing a microfluidic device how well it performs over time is one of the key areas of consideration. This microfluidic device performance is affected significantly by the level of adhesion between the patterned polydimethylsiloxane (PDMS) component and the mating silicon containing surface. When developing or optimizing a process this adhesion is measured by producing a feature in the device of a known diameter and increasing the pressure in the feature until the force generated by this pressure starts to separate or burst the device. This delamination is known as “Burst Pressure”. In this article we will discuss some of the key contributing factors in the optimization of producing a microfluidic device with good adhesion leading to good burst pressure leading optimized microfluidic device performance.

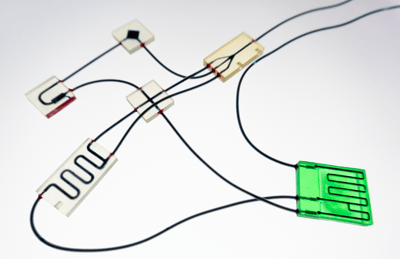

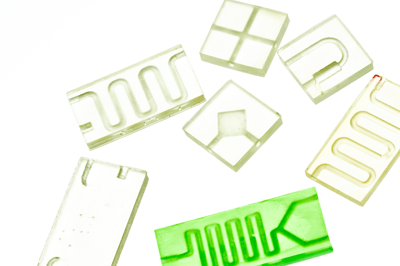

The term microfluidic device is a broad term used to describe many different configurations of assembly method or application. Some of these would be continuous-flow microfluidics, droplet-based microfluidics, digital microfluidics, particle detection microfluidics, open microfluidics, microfluidic-assisted magnetophoresis and DNA chips (microarrays). Microfluidic devices are created to analyze samples by using less fluid volume while reducing or managing sample interaction handling. These devices allow users to generate multi-step processes requiring a low level of expertise and much functionality in a small space and relatively low cost.

A few applications of microfluidics include detecting toxins, medical diagnostics, drug delivery, drug discovery, artificial organs, microscale chemical production, combinatorial synthesis and assays, environmental sensing, analyzing DNA sequences, micro propulsion, microscale energy systems and creating inkjet printing devices. Some important assets of microfluidic devices consist of faster reaction time, enhanced temperature control, analytical sensitivity, straightforward automation, parallelization, and integration of lab routines in a single device. The manufactured devices also benefit from being inexpensive as they do not involve various costly pieces of equipment.

A few applications of microfluidics include detecting toxins, medical diagnostics, drug delivery, drug discovery, artificial organs, microscale chemical production, combinatorial synthesis and assays, environmental sensing, analyzing DNA sequences, micro propulsion, microscale energy systems and creating inkjet printing devices. Some important assets of microfluidic devices consist of faster reaction time, enhanced temperature control, analytical sensitivity, straightforward automation, parallelization, and integration of lab routines in a single device. The manufactured devices also benefit from being inexpensive as they do not involve various costly pieces of equipment.

The key to creating a well-bonded microfluidic device is to have good manufacturing practices to remove process variation whenever possible. Small shifts in process variability can have a large influence in the performance of a microfluidic device. Controlling all aspects of the process to insure repeatability of aspect and drive out reproducibility issues controlling final performance of a device. Often the reason for a shift or variation in finished device performance is nearly impossible to understand or identify when observing the performance of a completed microfluidic device. When there is an aspect in your process steps that is not carefully defined and controlled a shift in parameters during the process, or an element of craftsmanship is introduced leading to a change in burst pressure or device performance in a finished product.

One of the first process steps that are a critical point to optimize burst pressure in microfluidic device manufacturing is to optimize the PDMS, catalyst mixing. Carefully measuring the ratio of PDMS to catalyst is obvious to device performance and is often executed with great care. However, controlling the mixing method, application of hardware, and time to ensure the catalyst is fully incorporated without having micro pockets of unincorporated catalyst in a cured PDMS mixture is often overlooked. This oversight often leads difficult to troubleshoot variation in device performance and burst pressure.

Once a sample of PDMS is mixed well special consideration must be used to ensure that all the air pockets and micro bubbles in the mixture are removed. Outgassing the fluid mixture in a vacuum chamber requires control and care. This outgassing is often applied before and during casting of the PDMS slab. Post cure inspection of the PDMS slab surface, channels and features with a microscope can expose these variations in surface finish. Variation in surface finish or feature shape can lead to variation in device performance and burst pressure.

At this point in the process the most important influence on device performance and burst pressure is to keep the sample clean during the entire process. Micro particulate and smearable contaminants can accumulate on the surface of PDMS slabs, mating silicon containing parts, tooling, alignment fixtures, storage, or even exposure to the air containing microparticles or fibers. This particulate contamination interferes with the activated PDMS surface coming in contact with the mating surface. If the surfaces can not come in contact they can not bond. The environment where the PDMS is mixed, cured, handled, stored, transported, inspected, and processed should be clean from airborne particulate and contaminants. A clean particle free workspace is essential to bonding, device performance, and burst pressure.

At this point in the process the most important influence on device performance and burst pressure is to keep the sample clean during the entire process. Micro particulate and smearable contaminants can accumulate on the surface of PDMS slabs, mating silicon containing parts, tooling, alignment fixtures, storage, or even exposure to the air containing microparticles or fibers. This particulate contamination interferes with the activated PDMS surface coming in contact with the mating surface. If the surfaces can not come in contact they can not bond. The environment where the PDMS is mixed, cured, handled, stored, transported, inspected, and processed should be clean from airborne particulate and contaminants. A clean particle free workspace is essential to bonding, device performance, and burst pressure.

PDMS slabs that have completed curing and sizing are ready for plasma activation and bonding. Plasma activation of the PDMS and the silicon-containing substrate for bonding is the industry proven way to bond the two materials with optimized device performance and burst pressure. The bond created between the surfaces will be covalent and this molecular sharing of electrons in the two surfaces is the best type of bond for these kinds of materials making the surfaces one molecule. If an adhesive were attempted to be used, it would plug or obscure the micro-channels and contaminate the device material. Plasma treatment activation and cleaning process before the two materials are bonded together is the best way to optimize device performance and bust pressure.

Plasma activation of the sample should not be taken lightly. To optimize device performance and burst pressure, control of steps in plasma processing is critical. Uniform treatment of the PDMS slab and silicon containing mating part must be exposed to uniform plasma of the same concentration of plasma disassociated active gas chemistry over the entire surface of the part. This plasma activation needs to be controlled and repeated from part to part, lot to lot, day to day and so on. The surface activation is increased to an optimized point with control of pressure, power, gas flow and chamber materials that do not generate particulate. This is critical because if you under treat your adhesion is low leading to poor adhesion and if you over treat the plasma starts to etch the sample and this leads to poor adhesion. The optimized carefully controlled plasma process activates the surfaces of the mating parts providing the best device performance and burst pressure.

Plasma activation of the sample should not be taken lightly. To optimize device performance and burst pressure, control of steps in plasma processing is critical. Uniform treatment of the PDMS slab and silicon containing mating part must be exposed to uniform plasma of the same concentration of plasma disassociated active gas chemistry over the entire surface of the part. This plasma activation needs to be controlled and repeated from part to part, lot to lot, day to day and so on. The surface activation is increased to an optimized point with control of pressure, power, gas flow and chamber materials that do not generate particulate. This is critical because if you under treat your adhesion is low leading to poor adhesion and if you over treat the plasma starts to etch the sample and this leads to poor adhesion. The optimized carefully controlled plasma process activates the surfaces of the mating parts providing the best device performance and burst pressure.

The best way to improve burst pressure in microfluidic devices is to ensure processes are completely repeatable and reproducible using plasma activation to provide the best possible covalent bonding of the surfaces. Problems can often occur when process steps are not consistently and uniformly produced when manufacturing product lots when scaling a process. Having a plasma system with a carefully designed control system is crucial to controlling process repeatability. This repeatability results in a high burst pressure, which will maximize device performance and minimize scrap increasing device yield and customer satisfaction in your product.

To learn more about how to improve burst pressure in Microfluidic devices, please read our eBook titled "How to Improve Burst Pressure and Yield in Microfluidic Devices."

Comments