Plasma Treatment Articles

Plasma Activation

|

2 min read

Modern plastics became a popular material for manufacturing a wide range of products in the early-mid 20th century. Today, plastic compounds are used to create an almost infinite variety of plastics that are used in everything from consumer goods to medical devices and avionics components. However, plastics in their original formulations can have limitations that make them unsuitable for some applications. Poor energy absorption, strength, colorability, chemical and water resistance are some of the characteristics that can curtail the use of certain plastics in some industries.

Fortunately, advances in plasma technology has changed all of that. Plasma treatment can now enable specific plastics to take on new characteristics that can open up entirely new uses for previously unsuitable compounds.

Filtration technology has been significantly improved by the use of plasma powder activation. It can now be used to make a particular plastic compound chemically active to a material by which it was previously unaffected. This improvement enables filter manufacturers to utilize new plastic materials to create products that are smaller, more effective, and less expensive -- plasma treatments covalently bond the filter chemistry to significantly improve filter performance.

Filtration technology has been significantly improved by the use of plasma powder activation. It can now be used to make a particular plastic compound chemically active to a material by which it was previously unaffected. This improvement enables filter manufacturers to utilize new plastic materials to create products that are smaller, more effective, and less expensive -- plasma treatments covalently bond the filter chemistry to significantly improve filter performance.

Plasma powder activation opens up new opportunities for companies interested in improved integration of a specific powder into a compound in which it previously was unable to uniformly disperse. By activating the powder with plasma it can be evenly dispersed within a fluid or polymer, such as rubber. The addition of powder to the liquid or polymer can shift the material properties to produce or improve valuable characteristics such as wear, friction, thermal stability, chemical resistivity, scratch resistance, UV resistance, firmness, and others.

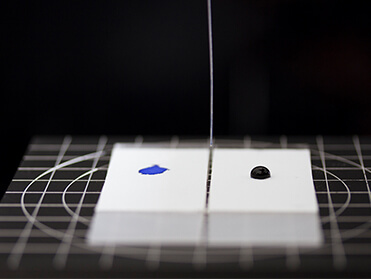

Plasma powder activation enables formerly hydrophobic polyethylene powder to become hydrophilic -- ideal for applications in which moisture absorption is a desirable characteristic. Polyethylene powder’s natural surface energy has no affinity to mix with water; but after the powder is plasma-activated, it readily mixes with water with little to no energy or effort.

Plasma treatments can also increase the surface energy of PE powder to provide dramatically improved tear propagation strength in some rubbers. And adding polyethylene powder to an industrial coating increases scratch resistance in the cured film.

Plasma cleaning and activation of diamond powder

Plasma cleaning and activation of diamond powderDiamond powder is used in different resin binders or ceramic binders to produce polishing abrasives, abrasive pastes, abrasives, or as loose abrasives. However, bonding to certain surfaces is often challenging – without activation or cleaning the material would fall apart. Fortunately, plasma powder activation changes the molecular characteristics of diamond powder, providing substantially improved contact and increasing the life and performance of products utilizing the versatile powder.

Polytetrafluoroethylene (PTFE), a compound commonly known by the brand name Teflon™, is widely used by manufacturers looking to create a non-stick surface for consumer, commercial, and industrial products; however, its desirable properties also make it difficult to uniformly incorporate in a solution. Plasma powder activation improves its capabilities to achieve more thorough dispersal and create a more uniform and reliable non-stick surface.

Pure carbon powder is a key element that improves conductivity in batteries and other electrical components. It, too, can be difficult to disperse in a solution without assistance. Plasma activation enables carbon powder to disperse in a solution without additives to dilute its purity, maximizing conductivity and thermal stability in the end product.

Plasma’s ability clean and activate powder enables manufacturers to create new materials with new and different properties for their applications. The equipment to plasma-activate and clean powders is highly effective and can be processed in vacuum chambers with volume ranging from as small as 2 liters to as large as 3600 liters, enabling producers to manufacture modified powders in whatever industrial volume they require.

To learn more about the benefits of plasma activation of powders in the manufacturing process, please read our article titled "Manufacturer’s Surface Activation Guide for Improved Adhesion."

Comments