Plasma Treatment Articles

Plasma Activation,

Plasma Treatment

|

4 min read

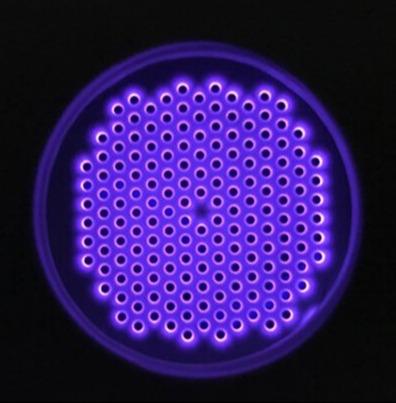

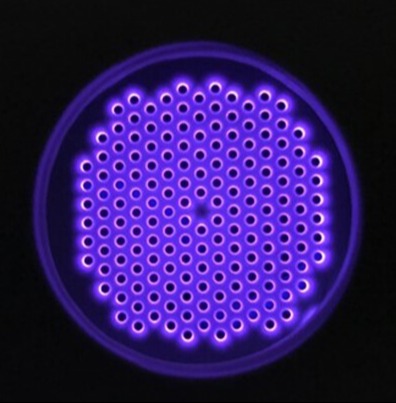

A dielectric barrier discharge is a popular method among manufacturers for producing large volumes of plasma at atmospheric pressure without a resonating chamber or high density plasma discharge. Plasma is produced by two electrodes with a dielectric between these electrodes to limit the current flow in the plasma. This low density plasma can be described as Dielectric Barrier Discharge or DBD for short.

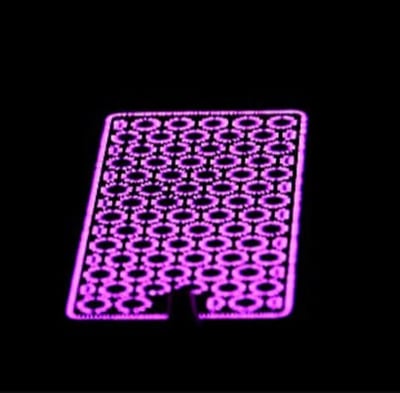

DBD configurations are generally characterized by the presence of an insulating material in the discharge path. Typically, dielectric materials such as glass, quartz, ceramics, enamel, mica, plastics, silicon rubber or teflon are used. DBD devices can be made in many configurations, typically planar, using parallel plates separated by a dielectric or cylindrical, using coaxial plates with a dielectric tube between them. In a common coaxial configuration, the dielectric is shaped in the same form as common fluorescent tubing and filled at atmospheric pressure with either a rare gas or rare gas-halide mix, with the glass walls acting as the dielectric barrier.

DBD configurations are generally characterized by the presence of an insulating material in the discharge path. Typically, dielectric materials such as glass, quartz, ceramics, enamel, mica, plastics, silicon rubber or teflon are used. DBD devices can be made in many configurations, typically planar, using parallel plates separated by a dielectric or cylindrical, using coaxial plates with a dielectric tube between them. In a common coaxial configuration, the dielectric is shaped in the same form as common fluorescent tubing and filled at atmospheric pressure with either a rare gas or rare gas-halide mix, with the glass walls acting as the dielectric barrier.

Because the electrodes used to generate the plasma can be made in any configuration -- including inside and outside of a tube or a large, flat, coplanar surface – DBDs are suitable for use in manufacturing processes where it is necessary to prevent contamination from other gases. Another attractive characteristic of DBD technology is that it enables material that comes in contact with the gas or the part to be activated to be used in both corrosive and non-corrosive manufacturing environments without the need of a vacuum.

Applications include semiconductor manufacturing, germicidal processes, polymer surface treatment, high-power CO2 lasers typically used for welding and metal cutting, pollution control, plasma display panels, and aerodynamic flow control, to name a few. DBD’s are particularly popular for fabric treatments, where they are used to modify the surface properties of the textile to improve wettability, improve adhesion and the absorption of dyes, and for sterilization. DBD plasma provides a dry treatment that doesn't generate waste water or require drying of the fabric after treatment. The typical DBD process for textiles involves rolling the material onto and off of storage coils, treating the material as it is continuously moved through the DBD.

The most popular type of industrial is a dielectric barrier discharge, particularly, a nanosecond, high voltage pulsed corona discharge at atmospheric pressure. Such a kind of discharge is often called a silent discharge. It has the big advantage that it can be applied for plasma treatment of large areas. The relatively small gap between the electrodes and the substrate allows strong electric fields and micro discharges that can treat a surface with relatively low power input.

Since the dielectric barrier discharge was invented by Siemens in the 1850s, it has become a working standard technology for ozone production. Since DBD reactors do not require a vacuum system, they can easily be applied, where the ozone is needed. This is of particular interest, for example, for water purification, where vast amounts of ozone are needed. DBD discharges can create this reactive molecule very efficiently, especially when the plasma source is driven by ns pulses with high voltage (25-40 kV) and high repetition rate (up to 2 kHz). If pure oxygen is used as feed gas, the energy cost for ozone production at room temperature can be as low as 2.5 kWh/kg. However, air can be used as working gas as well but with an increased energy demand of 5 kWh/kg. Although the energy cost for ozone production is very low, the energy density should be preferably high – up to about 70 W/dm³. In this power density regime, the production of O3 becomes highly efficient and the limit of 2.5 kWh/kg can be reached. Since the power density should be high for efficient ozone synthesis, it is advisable to have only small discharge gaps between the DBD electrodes. In modern ozone generators, the DBD electrodes mainly consist of glass or other dielectric tubes with a conductive thin film on the inner wall. These pipes are inserted into water-cooled steel tubes that are grounded and work as the counter electrode. The radial gap between those pipes should have high precision and be in the order of 0.1 to 1 mm. Microdischarges form in such thin gaps and lead to the excitation of oxygen molecules and subsequent ozone formation.

Activation of large areas of materials where the bonding application requires a small adjustment in surface energy. One of the most important uses currently in surface treatment is the activation of plastic foils in order to increase their surface energy prior to bonding, printing, coating, adhesion, or for cleaning it from organic compounds.

Activation of large areas of materials where the bonding application requires a small adjustment in surface energy. One of the most important uses currently in surface treatment is the activation of plastic foils in order to increase their surface energy prior to bonding, printing, coating, adhesion, or for cleaning it from organic compounds. Industrial applications of dielectric-barrier discharges have come a long way and, more recently, have substantially increased their market penetration. No doubt, this trend will continue.

Modern modeling and diagnostic tools have helped industry in general gain a better understanding of the fundamental processes that determine the discharge initiation and the resulting plasma chemical reactions. Miniaturization of electrode structures and discharge cells and the development of affordable, large throughput manufacturing technologies has resulted in an explosive growth of novel applications such as display device production. Dielectric barrier discharge has now become a readily-accepted option for manufacturing versus more typical atmospheric or low-pressure plasma systems.

If you would like to learn more about DBD and its suitability for your manufacturing process, contact the DBD experts here at Thierry to schedule a consultation. To learn about the benefits of plasma treatment in the manufacturing process, please read our article titled "Manufacturer’s Surface Activation Guide for Improved Adhesion."

Plasma: +1 (248) 761 9253

Distribution: +1 (248) 549 8600

Fax: +1 (248) 549 3533

info@thierry-corp.com

Comments