Plasma Treatment Articles

Plasma Activation

|

3 min read

Thermoplastic polyolefin (TPO) and thermoplastic polyurethane (TPU) are commonly used in commercial products. They are basically used in any injection molded product like automotive parts, sporting goods, and household items requiring better impact resistance and ductility over polypropylene.

One challenge manufacturers face when working with these materials is their low surface energy, which can make it challenging to achieve good adhesion for gluing, painting, or coating. Plasma activation is a process that can be used to improve the surface energy of TPO and TPU, making them more receptive to adhesives and coatings.

In this article, we'll take a closer look at TPO and TPU, explore the benefits of plasma activation, and learn how manufacturers can use this process to improve the adhesion of these materials.

TPO is an abbreviation for "thermoplastic olefin". It is a type of plastic made by combining two types of materials: olefins and thermoplastics. TPOs are known for their durability, flexibility, and resistance to both chemicals and heat. They are members of the TPE (thermoplastic elastomer) family. They usually have good hardness and flex fatigue resistance.

TPO is an abbreviation for "thermoplastic olefin". It is a type of plastic made by combining two types of materials: olefins and thermoplastics. TPOs are known for their durability, flexibility, and resistance to both chemicals and heat. They are members of the TPE (thermoplastic elastomer) family. They usually have good hardness and flex fatigue resistance.

TPOs were developed to create materials that would have the heat-sealability of polyolefins with the low-temperature flexibility of rubbers. TPOs are also designed to be tough and abrasion-resistant.

Overall, TPOs are very versatile materials that can be used in various applications.

A TPU, or thermoplastic polyurethane, is a type of elastomer that is characterized by its high flexibility and resistance to chemicals and temperature extremes. It is often used in applications where traditional rubber materials would not be suitable. TPU is a thermoplastic elastomer, which means that it can be molded and shaped when heated, but will return to its original state when cooled.

A TPU, or thermoplastic polyurethane, is a type of elastomer that is characterized by its high flexibility and resistance to chemicals and temperature extremes. It is often used in applications where traditional rubber materials would not be suitable. TPU is a thermoplastic elastomer, which means that it can be molded and shaped when heated, but will return to its original state when cooled.

TPUs are thermoplastic elastomers made up of block copolymers that include hard and soft segments. The hard segments are typically formed from diisocyanates, while the soft segments generally are long-chain diols or diol esters

The ratio of hard to soft segments, as well as the molecular weight and degree of crystallinity of the segments, can be varied to tailor the physical properties of the resulting polymer. As a result, TPUs exhibit a wide range of properties, including elasticity, transparency, and abrasion resistance.

TPUs are used in various applications, such as adhesives, coatings, sealants, and footwear. They can also be used as a soft engineering plastic or to replace PVC.

Polypropylene is one of the most common materials used in injection molding, but it is not always the best choice. TPO and TPU are two alternatives to polypropylene that can offer better performance in some applications.

TPO and TPU are thermoplastic polymers. Thermoplastic polymers are a type of plastic that can be melted and reformed multiple times. This makes them well suited for injection molding, as the molds can be reused many times.

TPO and TPU differ in their properties. TPO is more rigid than TPU, while TPU is more flexible. TPO also has a lower melting point than TPU. These differences give TPO and TPU different advantages and disadvantages in injection molded products.

TPO is often used in applications where rigidity is necessary, such as in automotive parts. TPU is often used in applications where flexibility is essential, such as in mobile phone cases.

In general, TPO and TPU can improve injection-molded products' performance over polypropylene. The best material for a particular application will depend on the required properties. These materials enable many commercial products and manufacturing them in high volume is relatively straightforward.

When it comes to commercial products, manufacturers must ensure that their branding is applied in the most effective way possible. In terms of manufacturing, activation can be used to improve the properties of a material.

When it comes to commercial products, manufacturers must ensure that their branding is applied in the most effective way possible. In terms of manufacturing, activation can be used to improve the properties of a material.

For example, materials with low surface energy like TPO and TPU are difficult to coat or get adhesives to bond because of their low surface energy. However, by using plasma activation, manufacturers can increase the surface energy of these materials to 105 dynes. This change in surface energy makes it more reliable to apply coatings, paints, and adhesives with a much stronger bond.

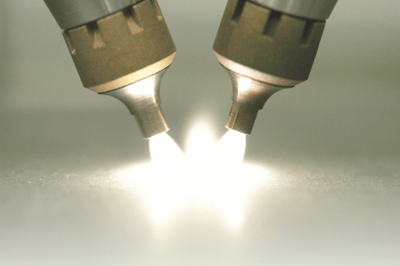

Previously, manufacturers would use mechanical abrasion to improve the surface quality for bonding of their materials. However, we know that abrasion alone does not significantly improve the adhesion of a surface that has low surface energy. Plasma activation is the most effective method for improving surface quality for coating, painting, and adhesion, and making sure that your products are up to the standards required. Depending on the materials and application, plasma activation can be performed using either atmospheric or low-pressure plasma systems.

When selecting a plasma system for activating TPO or TPU, it is essential to consider the type of material being processed, the desired outcome of the activation, and the specific constraints of the application. With proper selection and implementation, plasma activation can provide significant benefits for many TPO or TPU applications.

Comments