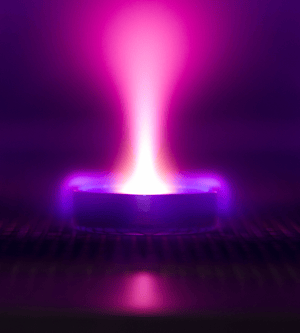

Plasma Density - Etch rates understood • Plasma uniformity

The term Plasma Density refers to the concentration or count of ionized gas particles in a given volume. This is also sometimes used to discuss the percentage of gas in a volume that is in an ionized state.

Typical gas plasma density defines a plasma state, ionized state, or the electron density in fully or partially ionized gases. The typical percentage of gas in an ionized state in a low pressure plasma system operating at 0.1 mbar to 0.6 mbar is about 4 to 14 percent of the gas in the vacuum chamber. This number depends on the power being applied to the gas in the system. We often discuss this power in wattage per square centimeter. This would be the total area of the electrode surface divided by the total wattage. This wattage / square cm typically is .01 w/cm^2 to 3 w/cm^2 for cleaning, activation, deposition and etching.

Typical gas plasma density defines a plasma state, ionized state, or the electron density in fully or partially ionized gases. The typical percentage of gas in an ionized state in a low pressure plasma system operating at 0.1 mbar to 0.6 mbar is about 4 to 14 percent of the gas in the vacuum chamber. This number depends on the power being applied to the gas in the system. We often discuss this power in wattage per square centimeter. This would be the total area of the electrode surface divided by the total wattage. This wattage / square cm typically is .01 w/cm^2 to 3 w/cm^2 for cleaning, activation, deposition and etching.

The main issue is to increase the plasma reaction you need to increase the plasma density when you increase the plasma density to high your part gets really hot. This becomes a thermal management issue of keeping your part and the plasma tool from getting to hot so there is not any damage. Industrial plasma operating above 3 watts / square cm will exhibit an increase in etch rate or deposition rate when compared to lower energy plasma processes. However these processes will require thermal management or cooling of the electrodes and work handling tooling in the vacuum chamber to prevent damage to process materials.

To learn more about the use of plasma in manufacturing, please read our eBook titled "Manufacturer’s Surface Activation Guide for Improved Adhesion."

Plasma: +1 (248) 761 9253

Distribution: +1 (248) 549 8600

Fax: +1 (248) 549 3533

info@thierry-corp.com