Plasma etching can remove layers of materials in order to create micro designs on the surface, but in order to make the designed patterns an etching mask is placed on the surface to be used like a stencil for the plasma. The plasma will not etch out the material below the mask. Some etching masks are made of organic material and are called photoresists. After etching, these masks need to be removed and that process is called

oxygen plasma etching or plasma ashing.

Oxygen plasma etching is a necessary step in the production of silicon wafers used in the fabrication of integrated circuits.

How Oxygen Plasma Etching is Accomplished

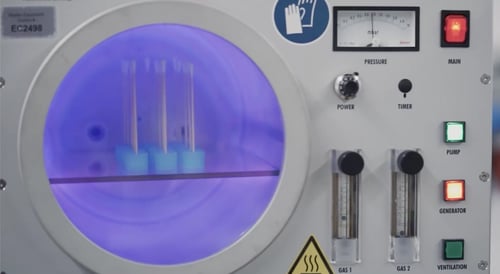

Oxygen plasma etching is done using low-pressure plasma systems. Oxygen is used as the precursor gas and is channeled into the vacuum chamber with the wafer. Then, high power radio waves are applied in the chamber and this, along with the low pressure of the vacuum chamber, causes the oxygen molecules to ionize, forming plasma. The oxygen plasma etches the photoresist by turning it into ash. The ash is then removed through the vacuum pump. This is why oxygen plasma etching is usually referred to as ashing.