Corona Discharge - Enhancing adhesion capabilities

In the manufacturing world, specific materials are preferred for producing specific products. While those materials may have positive characteristics such as malleability, strength, and heat resistance, for example, they may not have the surface energy to accept adhesives, coatings, paints, or printing well. If those treatments don’t adhere properly, they peel, flake, and fail. The result is a low-quality product.

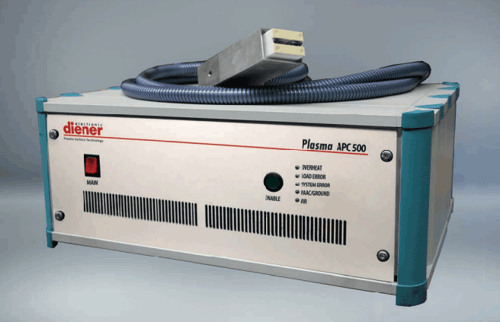

The low surface energy of certain materials often leads to poor adhesion of inks, glues, and coatings because they possess significantly high surface energies. To achieve optimum adhesion, it’s vital that the base material’s surface energy is equal to or higher than the surface energy of the substance which is applied to it, such as an adhesive or paint. Fortunately, a corona discharge can be used to effectively activate a surface in order to make it more receptive to a coating.

The low surface energy of certain materials often leads to poor adhesion of inks, glues, and coatings because they possess significantly high surface energies. To achieve optimum adhesion, it’s vital that the base material’s surface energy is equal to or higher than the surface energy of the substance which is applied to it, such as an adhesive or paint. Fortunately, a corona discharge can be used to effectively activate a surface in order to make it more receptive to a coating.

Corona discharge treatments are highly effective on virtually any surface format including dimensional objects, sheets, and roll goods that are handled in a web format. Corona discharges are widely used to treat a variety of materials and products in the plastic film, extrusion, and converting industries, including:

There can be a variety of effects on surfaces that are treated with corona plasma. It is known, for example, that fluoroplastics like fluorinated ethylene propylene (FEP) or polytetrafluoroethylene (PFTE) exhibit improved adhesion after the treatment. This allows painting or printing on such material, which would be much harder on non-treated surfaces. On natural fibers like wool, corona discharges can enhance wettability and prohibit the shrinking of the fabrics.

In other experiments on polymers like low-density polyethylene (LDPE), this kind of plasma treatment leads to changes in the surface roughness and alters the hydrophobicity of the substrate. The big advantage is that corona plasmas can also be ignited at atmospheric pressure and in (partly) reactive gases such as air, oxygen, or nitrogen. Another important point is that there are relatively few ions or free electrons present. Thus, no actual electrical breakdown occurs and the surface treatment itself is quite mild.

Nevertheless, there is also the possibility that the surface chemistry itself is altered. It has been shown, for example, that polypropylene (PP) films incorporate oxygen into the surface layer, which then changes the wettability drastically.

Corona treatment of non- conductive and polymer surfaces can also lead to improving the adhesion between them. The range of polymers is quite wide. Improved adhesion was also reported for PEEK or PET.