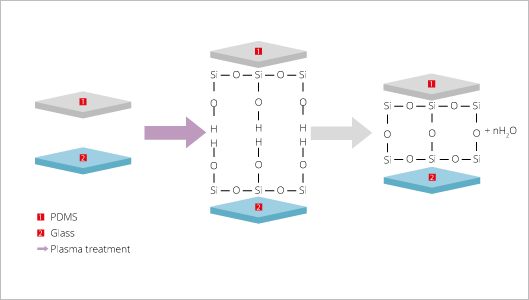

An important field for the application of low pressure plasma is the bonding of microfluidic devices from polydimethylsiloxane, (PDMS). PDMS is important in the manufacturing of microfluidic components when activated with oxygen plasma. When a PDMS component and a silicon containing structure are plasma activated they are able to bond together without an adhesive. This method of bonding without an adhesive enables production of smaller features versus using an adhesive. An interesting aspect is that microfluidic channels can be either hydrophilic with a low contact angle or hydrophobic with a high contact angle, depending on the area of utilization.

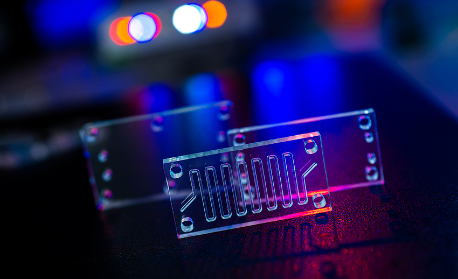

PDMS is a castable inert silicone that is used to take on the shape or form of the microfluidic channels and structures of the mold it is cast into. These casted structures are formed from raised shapes produced in the bottom of a mold. When the PDMS is cast in the mold and removed, the shapes in the bottom of the mold are transferred into the casted part.

These casted parts are then placed in oxygen plasma with the glass or silicon containing mating parts. When the parts are activated with oxygen plasma and then placed together with precision these parts will bond. The bond characteristics are covalent, meaning the PDMS part and the mating part share electrons producing a very strong bond.

When bonding PDMS devices it is important to determine if you require equipment for a simple proof of ability or tooling to optimize and repeat the process in volume. A wide range of products are available to bond PDMS. Understanding the subtle differences is important to ensure your application of plasma treatment is successful.

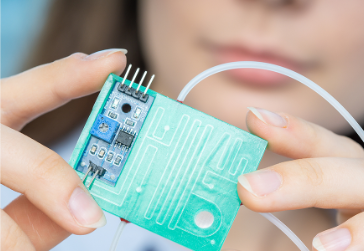

The application of producing microfluidic devices is relatively new technology with applications in industries performing process evaluation of fluid chemistries. The ability to reduce the size of the fluid testing hardware and the volume of the fluid required to test through the application of microfluidics are the key criteria driving the industry. These key variables determine the need of the medical industry, biotech and others to continually apply these design aspects to their individual needs.

Here is a more exhaustive list of industries that use PDMS, very often in combination with plasma surface treatment or plasma coating technologies:

PDMS stands for polydimethylsiloxane, which is also known as dimethylsiloxane or dimethicone. It is an organic polymer that is based on silicon, which makes it also a member of the so-called organosilicon compounds. The properties of PDMS are quite remarkable, since it is optically clear, chemically inert and, thus, non-flammable, non-toxic and biocompatible. These properties enable a wide range of applications. It is used in the food industry to suppress foaming of liquids. In the medical field it is applied for manufacturing contact lenses or medical devices. PDMS is also used in cosmetics as an important ingredient in hair products or skin lotions. It can also be used as a remedy for head lice or fleas on pets. Depending on the usage PDMS coatings can either be obtained with sol-gel methods or via plasma deposition. For the latter, both atmospheric and low-pressure plasma can be utilized. After a plasma treatment of a PDMS surface the polydimethylsiloxane can be either hydrophobic or hydrophilic, depending on the plasma parameters. The most important aspect is the composition of the feed gas.

PDMS is an important raw material in microchips for biomedical applications. Such microchips can be used, for example, as monitoring devices for micro dialysis, contactless conductivity detection or genetic analysis. A quite recent development is the printing of PDMS patterns with air plasma assistance. This plasma treatment allows a simple fabrication of such patterns directly on large area gold or PDMS substrates. Other researchers have demonstrated the possibility of surface coating of bonded dimethylsiloxane microchannels with an atmospheric pressure plasma source. On the other hand, there are also PDMS based microchips, which can be plasma treated and coated with other polymers. For this purpose the surface has to be extremely clean and is, thus, prepared with low or atmospheric pressure plasma (mostly with oxygen).

PDMS can stick to glass even permanently when the glass substrate is correctly prepared. This preparation often includes a plasma cleaner or another form of plasma treatment, which cleans and activates the surface before the PDMS can stick to the substrate. The cleanliness of the glass is of utmost importance because the PDMS has to come in direct contact with the glass. Some research suggests that the additional use of oxygen plasma enables the formation of chemical bonds between glass and PDMS. However, there are many applications where a bonding between PDMS and some polymer is needed. A very prominent example is poly(methacrylate) or PMMA. Again, plasma surface treatment can achieve exactly this – either PDMS bonding to PMMA or even using PDMS as an intermediate layer to achieve adhesion between PMMA and glass. Plasma-treated polymers can also exhibit a greatly enhanced adhesion with plasma-treated PDMS. If such a process is also accompanied by heat treatment, one can even renounce adhesives entirely.

Combinations of PDMS and metals, such as copper, gold or silver are of particular interest, since they enable a broad range of useful applications. Either the PDMS is coated with metal or vice versa. Plasma treatment of the PDMS is very important as it has been proven that it can reduce cracking and the formation of wrinkles in thin metal films. Oxygen plasma is also commonly used to deposit stable metal layers on PDMS, as well as obtaining micro and nano patterned metal surfaces with large surface area.

Control Cabinet:

W 310 mm H 330 mm D 420 mm

Chamber:

Ø 3.9 in, L 10.9 in

Chamber Volume:

2

Gas Supply:

1 gas channel via needle valve

Generator:

1 pc. with 40 kHz

(optional: 13.56 MHz or 2.45 GHz)

Control:

Semi-Automatic

Control Cabinet:

W 310 mm H 330 mm D 420 mm

Chamber:

Ø 3.9 in, L 10.9 in

Chamber Volume:

2

Gas Supply:

Mass flow controllers

Generator:

1 pc. with 40 kHz

(optional: 13.56 MHz or 2.45 GHz)

Control:

Touch Screen

Control Cabinet:

W 600 mm H 1700 mm D 800 mm

Chamber:

Ø 10.5 in, L 16.5 in

Chamber Volume:

24

Gas Supply:

2 gas channel via needle valve

Generator:

1 pc. with 40 kHz

(optional: 13.56 MHz or 2.45 GHz)

Control:

Semi-Automatic

Control Cabinet:

W 600 mm H 1700 mm D 800 mm

Chamber:

Ø 10.5 in, L 16.5 in

Chamber Volume:

24

Gas Supply:

Mass flow controllers

Generator:

1 pc. with 40 kHz

(optional: 13.56 MHz or 2.45 GHz)

Control:

PC

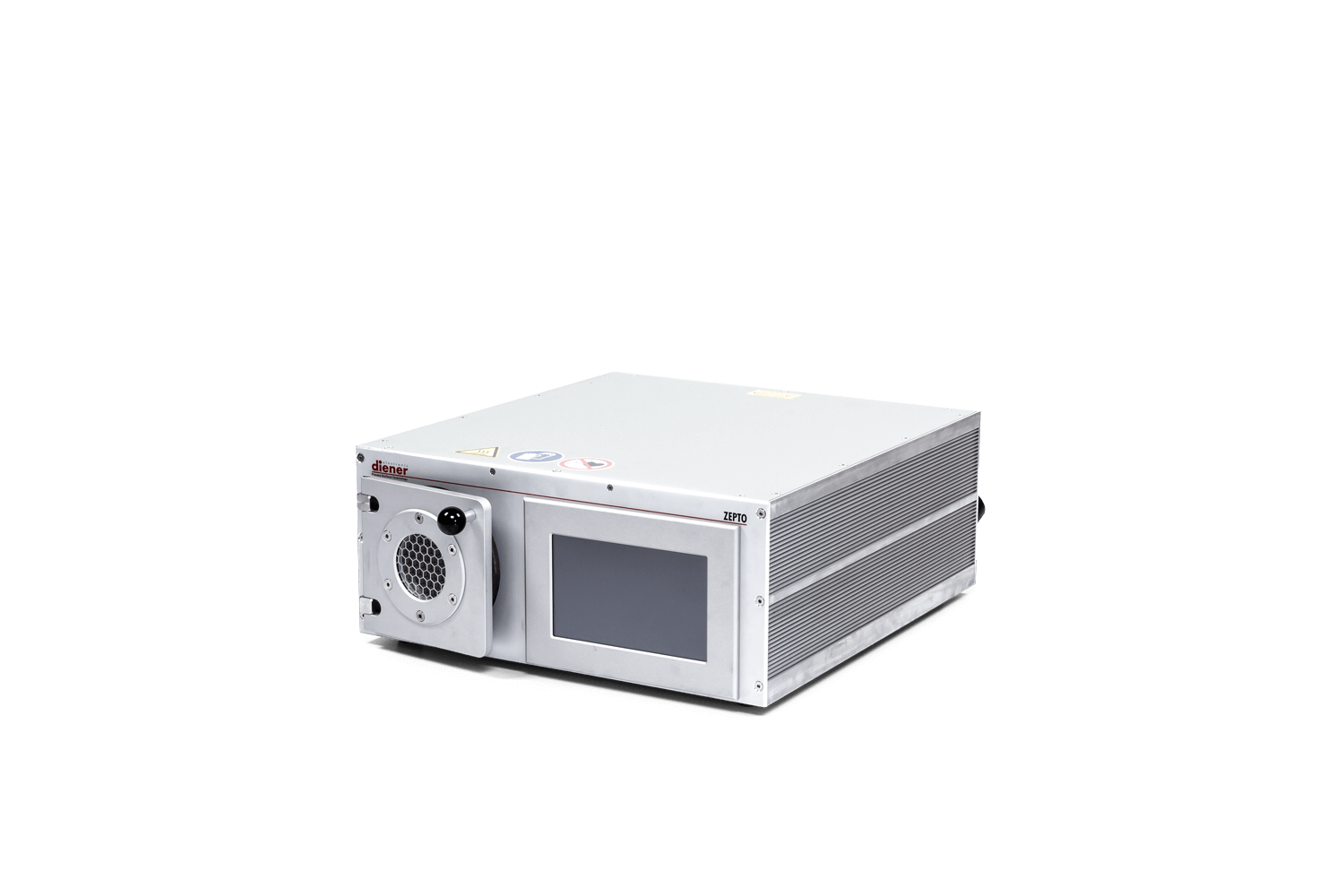

Control Cabinet:

W 425 mm H 185 mm D 450 mm

Chamber:

Ø 4.1 in, L 11.8 in

Chamber Volume:

2.6

Gas Supply:

Mass flow controllers

Generator:

1 pc. with 40 kHz

(optional: 13.56 MHz)

Control:

Touch Screen

Control Cabinet:

W 425 mm H 275 mm D 450 mm

Chamber:

Ø 8.3 in, L 11.8 in

Chamber Volume:

10.5

Gas Supply:

Mass flow controllers

Generator:

1 pc. with 40 kHz

(optional: 13.56 MHz)

Control:

Touch Screen

Plasma: +1 (248) 761 9253

Distribution: +1 (248) 549 8600

Fax: +1 (248) 549 3533

info@thierry-corp.com