Aerospace: Ultra-chemically clean surfaces for propellant and oxidizer valving, pumps, fasteners and structural bonding components.

Automotive: Effective method to remove mold release and reliably cleans surfaces prior to sealing, bonding, painting, or coating processes.

Consumer Goods: Plasma cleaning and activation are used to clean and treat polymer and composite components prior to adhesion or coating processes.

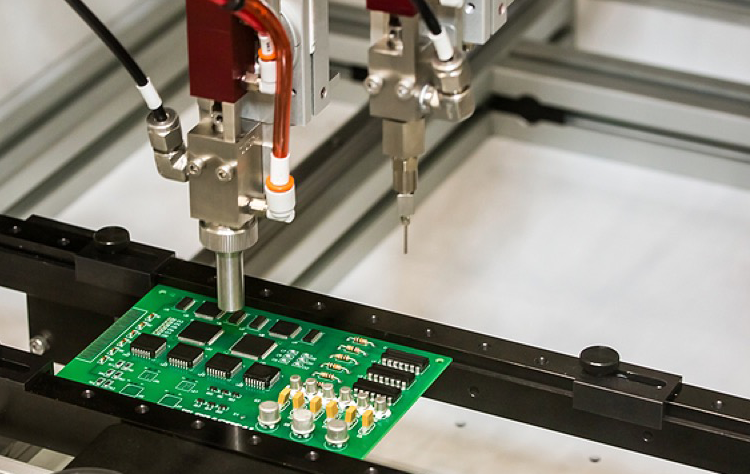

Electronics: Employed in electronics to reduce oxides, clean and degrease metal surfaces prior to bonding, soldering, circuit printing, and conformal coating.

Medical Devices: Provides an unrivaled solution that produces chemically clean surface free of pyrogens, foreign material and removes trace contaminants in micro-structures or fine cracks in materials.

Rubber Processors: Effectively and reliably removes mold release and lubricants that can later cause down-stream adhesion and bonding processes to fail.

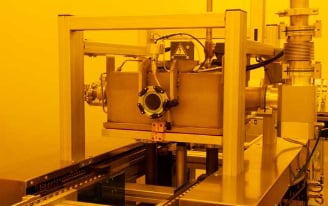

Semiconductor: Plasma cleaning and activation is applied to wafers, bond pads, and lead frames to promote adhesion and improve the reliability of secondary processes.

Solar: Used to clean bond pads and conductive materials for improved conductivity and reliability of the device and package electrical connections.

Textiles: Removes manufacturing contamination from textiles to improve coating durability and longer performance life.

Low Pressure

These systems apply energy to a gas in a vacuum system to produce a stable source of gas plasma.

These custom systems enable manufacturers a design that fits seamlessly into their established manufacturing line.

We are dedicated to creating and delivering surface modification solutions that improve the manufacturing process and profitability of our customers. Our full-service staff is committed to providing complete solutions from concept to delivery. Before a client buys or rents a plasma system we guide them with plasma process development to ensure their success. Contract service is also an available service option.