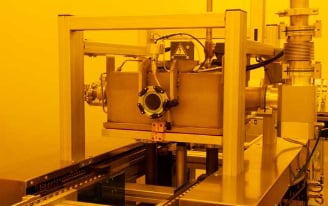

Among other industries, it’s used in the semiconductor industry to produce thin films. In CVD, a substrate is exposed to chemical vapors which react and decompose on the surface of the substrate to produce a layer, coating, or material used for input into another process with desired properties.

Among other industries, it’s used in the semiconductor industry to produce thin films. In CVD, a substrate is exposed to chemical vapors which react and decompose on the surface of the substrate to produce a layer, coating, or material used for input into another process with desired properties.

PECVD is a technique designed to create thin or ultrathin films on the surface of a substrate.

Advantages of this plasma coating technique include:

email: plasma@thierry-corp.com | phone: +1 (248) 549-4581

Request a Discovery Call Today!

We'll help you get to the heart of your coating challenges!

Our plasma treatment experts will:

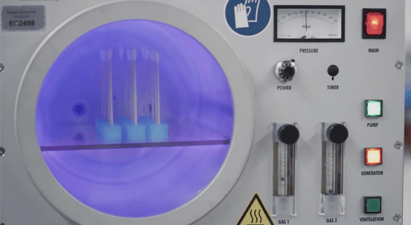

Low Pressure

These systems apply energy to a gas in a vacuum system to produce a stable source of gas plasma.

Atmospheric Pressure

These systems apply air or gas plasma to a small area of a part without treating the entire part.

Custom Industrial

These custom systems enable manufacturers a design that fits seamlessly into their established manufacturing line.

Vacuum Chambers

Many manufacturing processes require high altitude testing or material drying vacuum chamber solutions.

We are dedicated to creating and delivering surface modification solutions that improve the manufacturing process and profitability of our customers. Our full-service staff is committed to providing complete solutions from concept to delivery. Before a client buys or rents a plasma system, we guide them with plasma process development to ensure their success. Contract service is also an available service option.