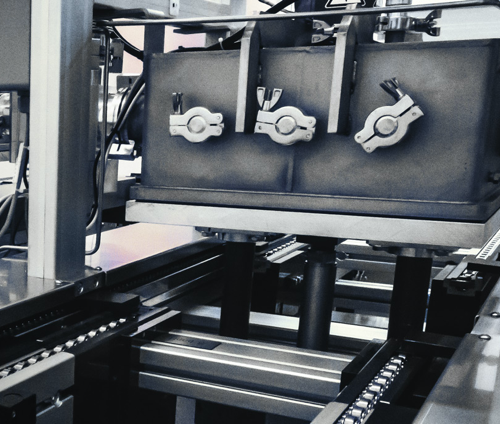

Custom industrial plasma systems are used to enable and improve new or existing product lines. The process of producing a product in volume can have many challenges. Improving quality and reliability with a controlled method of activation, cleaning, etching or coating of parts in volume are the primary advantage of having a custom industrial plasma system.

Request a Low Pressure Plasma Quotation

Atmospheric pressure plasma is suitable for a wide range of applications. Primarily, the systems are optimized for high volume plasma treatment of communication device surfaces in manufacturing.

For more than 30 years, we've acquired relevant experience with Industrial Plasma Systems to become a technology leader in the implementation and use of plasma systems.

Request A Quote

Plasma cleaning and activation for adhesion optimization in a high volume process with a short takt time is one of the key uses of an industrial plasma system.

Plasma etching or using plasma to reduce an oxide in a high volume manufacturing process is one of the key applications of large scale industrial plasma systems.

Plasma coating a large number of elastomeric seals or O-rings using plasma processing in a high volume manufacturing process is a good application for custom industrial plasma systems.

Another application of plasma coating is parts that require a hydrophobic coating. An example of this is pipet tips for medical or biological experimentation.

Control Cabinet:

W 600 mm H 1700 mm D 800 mm

Chamber:

W 15.8" x H 15.8" x D 24.6"

Chamber Volume:

100

Gas Supply:

Mass flow controllers

Generator:

1 pc. with 40 kHz

(optional: 13.56 MHz or 2.45 GHz)

Control:

PC

Control Cabinet:

W 600 mm H 1700 mm D 800 mm

Chamber Volume:

120

Gas Supply:

Mass flow controllers

Generator:

1 pc. with 40 kHz

(optional: 13.56 MHz or 2.45 GHz)

Control:

PC

Control Cabinet:

W 600 mm H 2100 mm D 800 mm

Chamber:

W 15.8" x H 23.6" x D 24.6"

Chamber Volume:

150

Gas Supply:

Mass flow controllers

Generator:

1 pc. with 40 kHz

(optional: 13.56 MHz or 2.45 GHz)

Control:

PC

Control Cabinet:

W 600 mm H 2100 mm D 800 mm

Chamber Volume:

600

Gas Supply:

Mass flow controllers

Generator:

1 pc. with 40 kHz

(optional: 13.56 MHz or 2.45 GHz)

Control:

PC

Control Cabinet:

W 600 mm H 2100 mm D 800 mm

Chamber Volume:

600

Gas Supply:

Mass flow controllers

Generator:

1 pc. with 40 kHz

(optional: 13.56 MHz or 2.45 GHz)

Control:

PC

Control Cabinet:

W 600 mm H 2100 mm D 800 mm

Chamber Volume:

7000

Gas Supply:

Mass flow controllers

Generator:

1 pc. with 40 kHz

(optional: 13.56 MHz or 2.45 GHz)

Control:

PC

Control Cabinet:

W 600 mm H 2100 mm D 800 mm

Chamber Volume:

12600

Gas Supply:

Mass flow controllers

Generator:

1 pc. with 40 kHz

(optional: 13.56 MHz or 2.45 GHz)

Control:

PC