How Atmospheric Plasma Systems Are Used

Atmospheric pressure plasma is suitable for a wide range of applications. Primarily, the systems are optimized for high volume plasma treatment of communication device surfaces in manufacturing. For example in the cleaning and activation of polymers, metals, ceramic, glass and composite materials. Due to their unique innovative design, atmospheric pressure plasma systems are suitable for use with robots and for integration in existing, automated production lines.

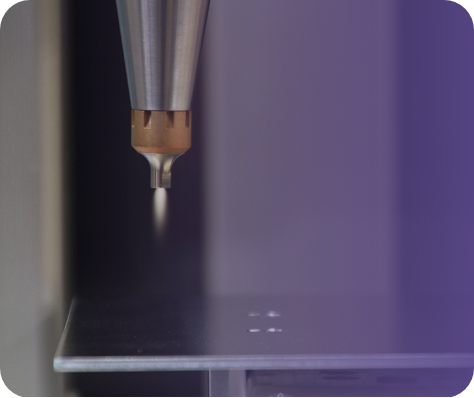

Atmospheric plasma is moved across the part which exposes the treated area to a stream of ionized gas plasma. The speed and distance of the applicator from the part determines the shift in surface energy or amount of treatment the target area receives.

While the plasma cleans and activates the surface on a molecular level, an additional cleaning effect is provided by blowing away loose particles. Atmospheric plasma systems allow for a truly continuous plasma process. The plasma applicator is connected to the supply unit with a flexible cable that allows for easy integration into existing robotic controlled manufacturing lines or moving the plasma source relative to the part.

Request A Quote